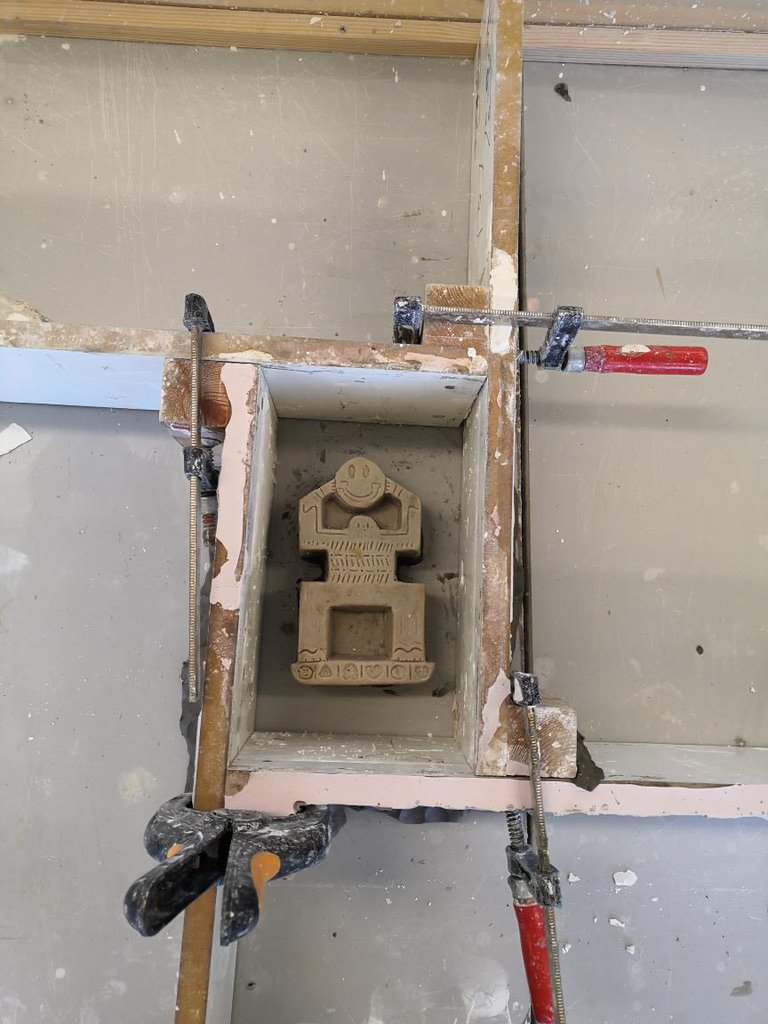

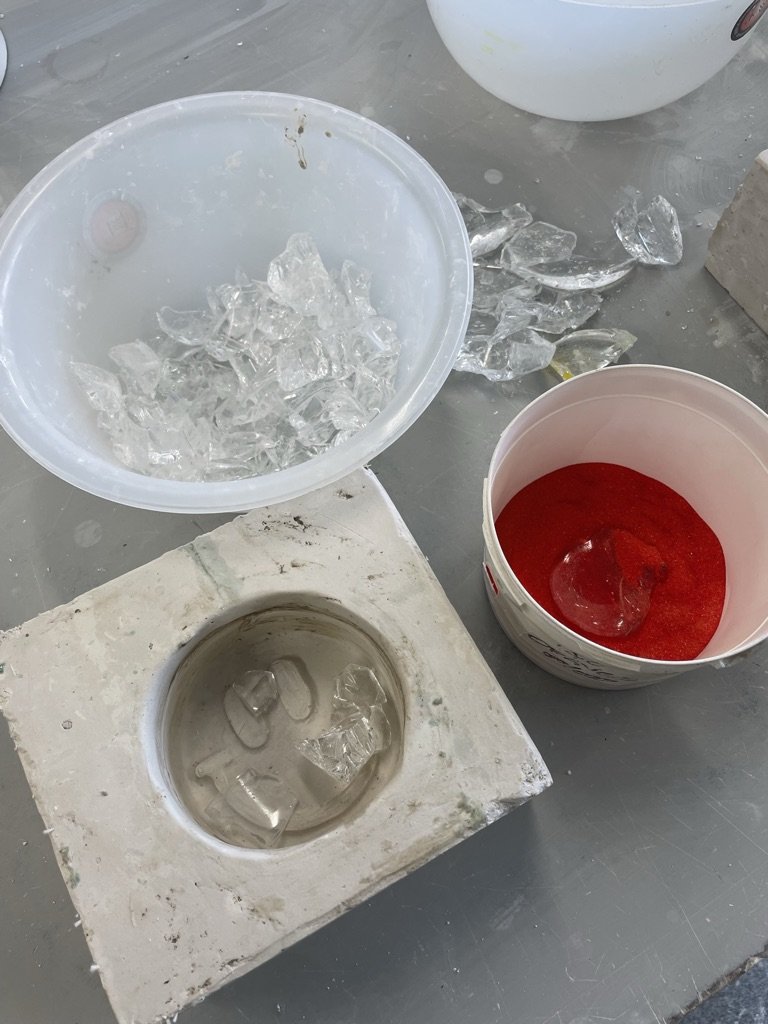

The furnace was turned off at the beginning of July so no more sandcasting but I was keen to explore potential of casting glass in a remade mold in the kiln so I did! s I have created two designs of ancient rave artefacts. Kiln casting is more refined in terms of the resulting image of object, making a wax copy means that fine detail is possible. A plaster flint mold is then made around this wax copy, once set the wax is steamed out and the cold is ready for layering the glass fragments and colour. This is put into the kiln for 5 day so the glass melts into the shape. Although the shape was predetermined but the mold itself, I loved the complete unknown of what was going to happen with the colour as I experimented with mixing left over colour that was available in the glass workshops.